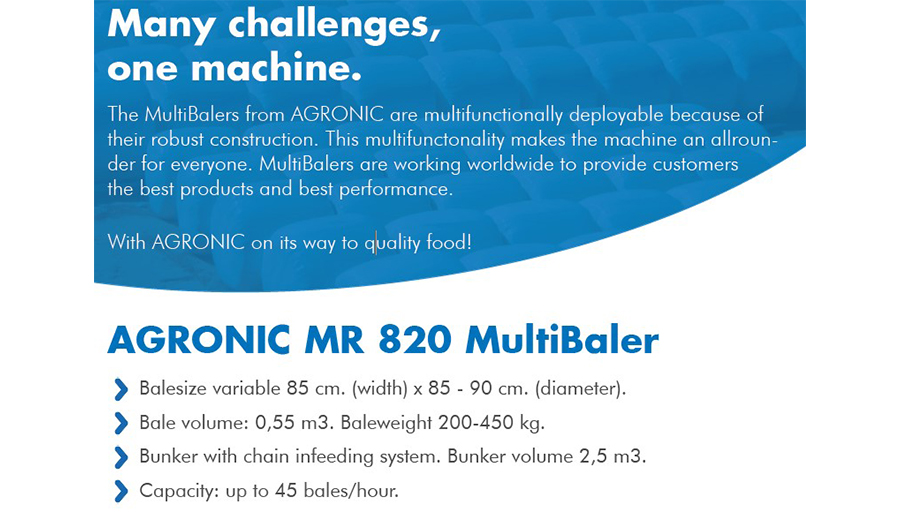

MultiBaler XL

The KNOLL MultiBaler XL is multi-functionally deployable because of his robust construction. This multi-functionality makes the machine the best all rounder of its kind. KNOLL MultiBalers are working worldwide to provide the best quality round bales and highest performance.

With KNOLL on its way to quality forage!

The development

In addition to the existing KNOLL MultiBalers (820/1220), the KNOLL MultiBaler XL is a completely new development. We have once again moved to the drawing board and de- veloped a machine that is unique.

Continuing on both the stationary and mobile use, this MultiBaler XL gives the opportunity to process a variety of materials in round bales.

Key feedback from you, the customer, underlined the need for comfort, ease of use, value for money, excellent reliability, intuitive and convenient controls, 100% connectivitynd the ability to work with the most demanding implements.

We keep you moving forward…

We have noticed that the development and demand for processing chopped or shredded materials in well-compacted round bales is increasing.

Adding value is more than just making a good machine. Our starting point is always: ‘‘what means valuable to our users?’’

The KNOLL MultiBaler XL is a new machine that makes work for the customer more pleas- ant, faster, better, and more reliable. It gives more possibilities, and in our view, that is what we can use to help you move forward, our motivation to keep developing.

Best quality feed for your livestock

With the KNOLL MultiBaler XL, Knoll Baling & Wrapping offers a unique machine and total

solution that can be used in a very economical way. Depending on the type of material and structure, different kind of materials can be compacted from 30% to 70%.

Every machine owner or customer you work for desires to process the best quality feed.

The highest quality silage can be guaranteed by processing it in bales.

Quality depends on many factors, but high compaction and the exclusion of oxygen in combination with the best processing capacity makes the KNOLL MultiBaler XL the right partner in this process.

Unique and versatile, the most efficient in its kind!

The KNOLL MultiBaler XL is unique. The only machine that can work both stationary and mobile. There is no need to change the work mode of the machine. Very simple and you can start working right away.

This feature provides versatility and more possibilities to use the machine effectively, with a better result in the end….. and happy users!

Stationary use

The MultiBaler XL is equipped with a large bunker at the front of the machine. This bunker can be easily loaded from above using various machines.

With a capacity of 8.00 m3, this bunker is the ideal way to process a variety of materials, both for agricultural and industrial applications.

Loading with any kind of loading equipment

The spacious infeed bunker can be loaded with any type of machine.

E.g. a tractor with a front load- er, wheel loader, crane or any other loading solution.

The bunker is equipped with side panels that can be folded down to facilitate loading.

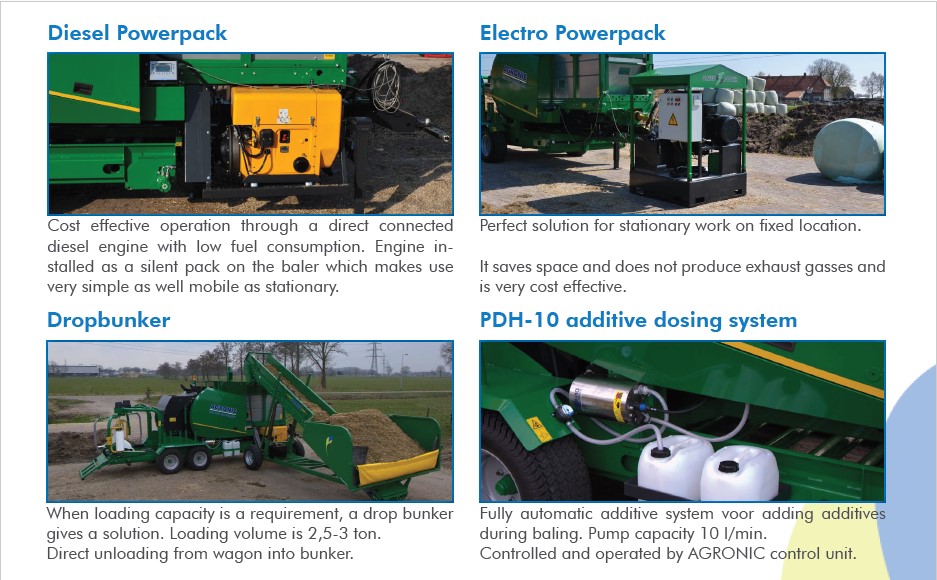

Using the Drop bunker V60120 for loading

When loading directly from a silage wagon, the ‘‘Drop bunker V60120’’ offers the solution for the demanding user.

This loading bunker (3.50 m3) is hydraulically driven and the feed speed can be perfectly ad- justed for any type of material by means of a throttle valve.

The MultiBaler XL distinguishes itself from any other machine on the market because it offers the possibility to use the machine directly in the field.

This simplifies use and often saves 1 to 2 extra work passes that are required for stationary use. The crop is processed into a bale immediately after chopping, which guarantees the very best end product.

Unique combination!

The KNOLL MultiBaler XL can be used mobile very efficiently:

- Direct in combination with the chopper (pto-driven)

- Driving next to the chopper, pulled by a tractor

- In combination with a tractor equipped with a chopper at the front

Various types of grass can also be processed directly in the field.

The KNOLL MultiBaler XL answers a fre- quently asked question. Is it possible to process chopped grass into bales? YES!

The MultiBaler XL was developed on the basis of the idea that it should be possi- ble to process various chopped/shredded materials into bales.

A variety of materials can be baled, for example grass, alfalfa, herbal mixtures, hemp, crimped grain, GPS etc.

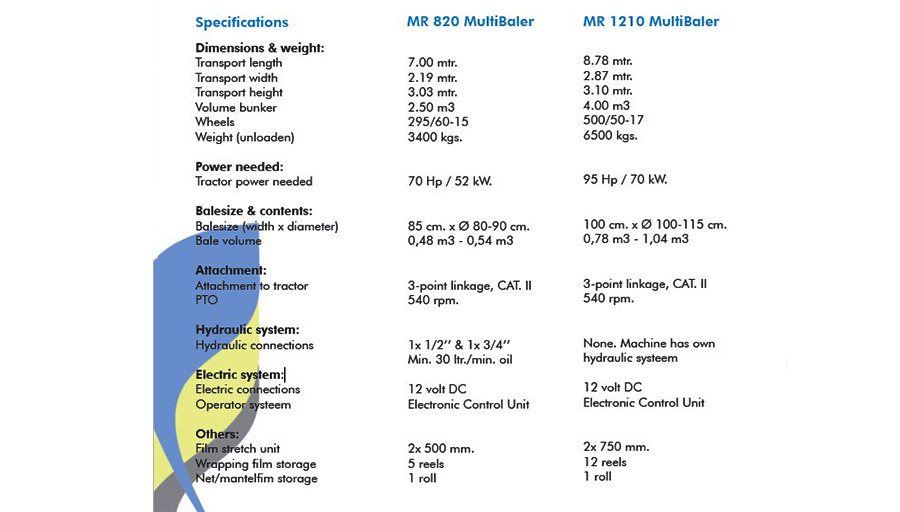

Basic specification of the machine

| Double wrapper arm with 750 mm. film |

Tandem chassis with flotation tyres 560/60 R22.5 |

| Automatic film break detection system |

Air brake system (two-line) for max. 60 km/h |

| Automatic adjustment of the wrapping speed for one roll |

Rimote® system for wireless connection of the machine for service and operation |

| Patented binding system for mantelfilm or net |

Integrated camera system with two camera’s |

| Bale chamber with 17 chamber rolls equipped with long-lasting slide bearings |

Integrated LED-light system equipped with 4 work lights |

| Patented Power-Grip-4 bale chamber belts (2 pieces) |

Automatic central lubrication system for oil and grease for all bearings and drive chains |

| Return system for recycling of crumb losses |

External keypads for quick operating of functions |

| Hydraulic baling pressure control system |

IQAN 10’’ TFT touchscreen operating console |

| Proportional hydraulic movable wrapper table |

12 reels additional wrapping film storage |

| On board Danfoss hydraulic system (load-sensing) |

5 reels additional mantelfilm/net storage |

| Air-cooled oil cooling system with reverse fan |

Special feed rotor for optimal control of crop flow |

Any kind of material can be baled!

You will be amazed by the possibilities that the KNOLL MultiBaler XL offers you!

Any type of material can be processed, from agricultural crops to industrial processing of waste products, we are happy to accept the challenge!

| Examples of other materials that can be baled with the KNOLL MultiBaler XL… |

| Transforming bulk material and other fine particle materials into round bales with high-density is where the KNOLL MultiBaler XL excels!

Our customers use our MultiBalers to bale a wide range of different materials. |

Alfalfa / Lucerne |

Dry manure |

| Crimped grain |

Saw dust |

| Sugar beet pulp |

Peat |

| Hemp |

Cotton |

Machines are provided with expertly compiled user manuals and parts information.

High-quality original spare parts. Everything in stock, fast delivery.

We are available 24/7 to help you with various communication tools.

The KNOLL MultiBaler XL is a robust machine. It has a strong and durable developed bale chamber, resulting in very well compacted bales. The film binding is working in an uncompli- cated way and works magnificently for all kinds of materials.

Due to the very well optimized control of the complete machine, the MultiBaler XL also achieves a good hourly output.

What made you decide to start working with an KNOLL MultiBaler XL?

Loading of the bunker with the optional ‘‘side loading conveyor’’ was of great importance to us, so we can unload quickly with our dosing trailer with side discharge system so we never have to drive back. Next to this, setting up the machine is easy and hardly noticeable in terms of the time required.

What kind of materials are you baling with the machine?

We mainly bale maize, corn cob meal, some sugar beet pulp. Our idea is to also bale GPS and possibly grass silage.

But from our experience you can bale anything with this machine.

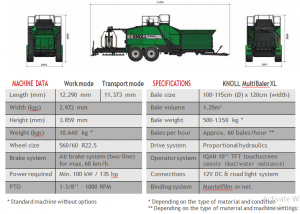

Technical details

The KNOLL MultiBaler XL can be used stationary or mobile after arrival at workplace to get started immediately.

The figure and overview below provide information on all the technical details of the machine and the power and connections required to operate the machine.

Work mode (mm)

Transport mode (mm)

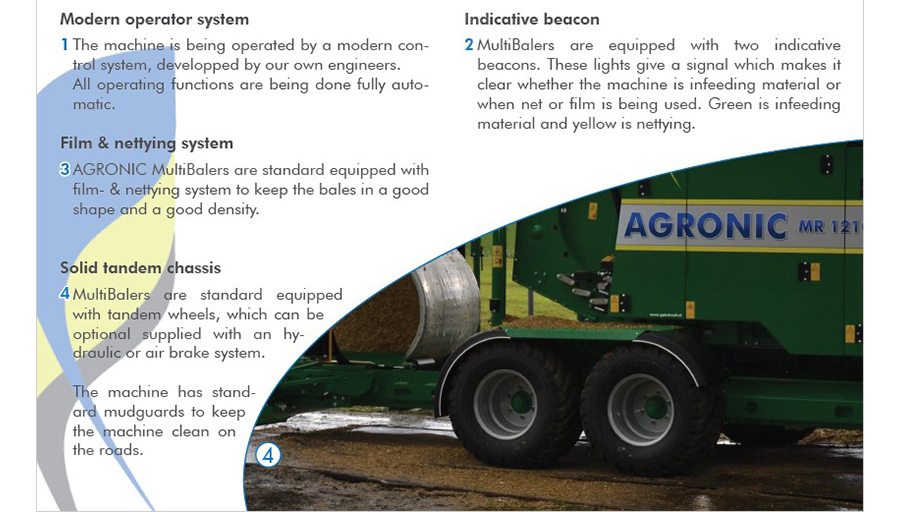

‘‘KNOLL & AGRONIC

moving forward together, success takes care of itself’’

A strong partnership for more than 25 years brings out the best in us.

Successful together in the development of durable and reliable ma- chines that create added value for our customers!